MCT summary

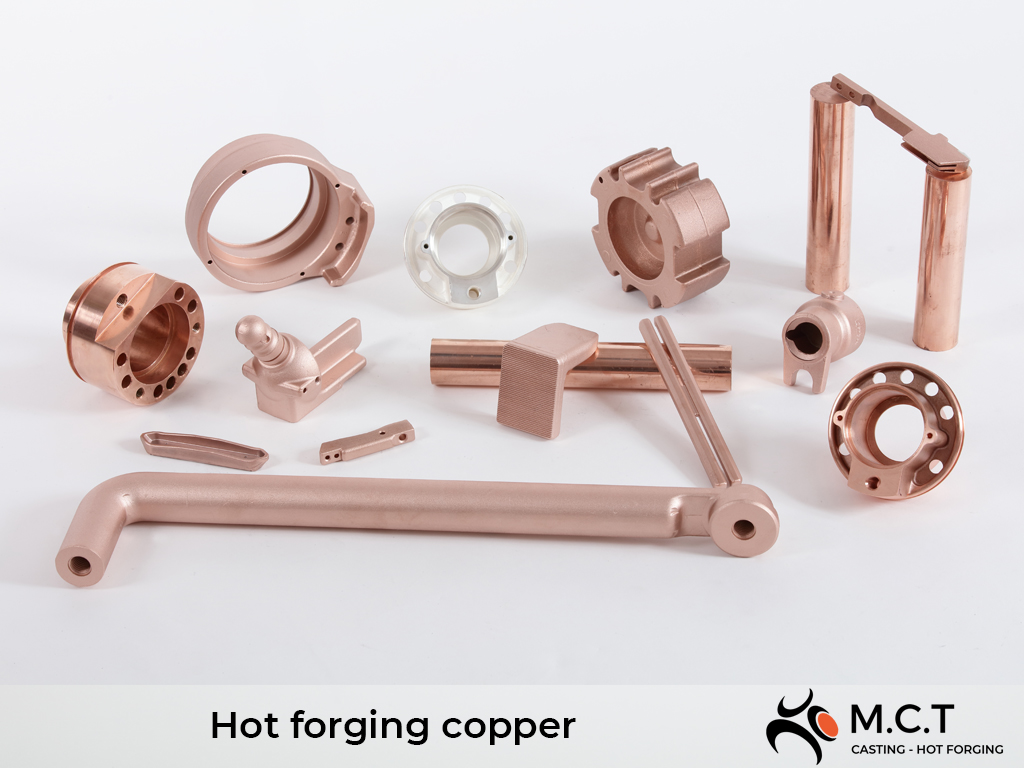

The MCT company builds metal parts with non-ferrous alloys. Here are the transformed non-ferrous metals :

Aluminium - Brass - Bronze - Copper - Zamak

The parts can be manufactured in three different ways :

High pressure aluminium, brass and zamak die casting

Micro Injection de Zamak de Sous-Pression

Foundry injection press of 120 to 640 tons

Coquilleuses quatre axes. (?)

Hot forging of brass, copper, bronze alloys

Presses and hot froging friction balancers of 100 to 1000 tons

Machining

Numerical machining on conventional machines

Transfer machine 6, 9 and 12 CNC postes 64 axes

Area treatment (polishing, chrome plating, nickel plating, tinning, silver, gilding, coppering, brassing, zinc plating, bichromatage, anodizing, painting)

design office Equiped with 3D volumic and surfaces software for the design of tools

Integrated tools manufacturing and maintenance workshop

Service contrôle muni de machine tridimensionnelle 3D surfacique et de spectromètre à étincelage. (?)

Quality certification : ISO 9001 : 2008