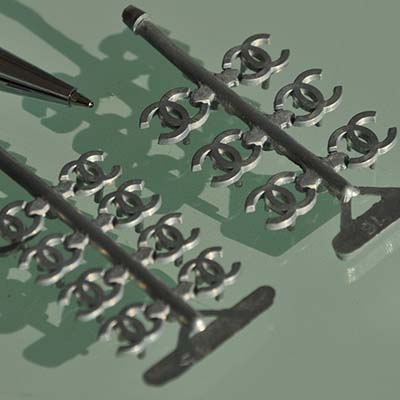

Micro injection of Zamak under pressure

Zamak micro-injection in a hot chamber makes it possible to produce parts weighing a few grams with the following technical advantages :

- Injection of complex and precise parts.

- Production of parts with up to four drawer movement axes in addition to the mould opening axes.

- Reduced production costs through very low metal feed loss and fire loss.

- Feeding in the direction of the parting line without 90° bends as in conventional presses.

- Quick mould change on the machine (cavities and drawers).

- In some cases, automatic separation of the feed (sprue/runner) and the part at the time of injection.

- Parts with little burr and therefore no need for cutting.

- Reduction of part finishing operations.

This technology also allows a reduction in the cost of moulds:

- The moulding parts contain only the impressions and cores without the need to invest in a heavy casing as in conventional presses.

- If the part requires drawers, the sliding systems are already included in the "cross" integrated in the machine structure.

- It allows a reduction in the number of impressions because the injection rates are fast and are adapted to large series.

- The indentations in the zamak injection have a long service life.