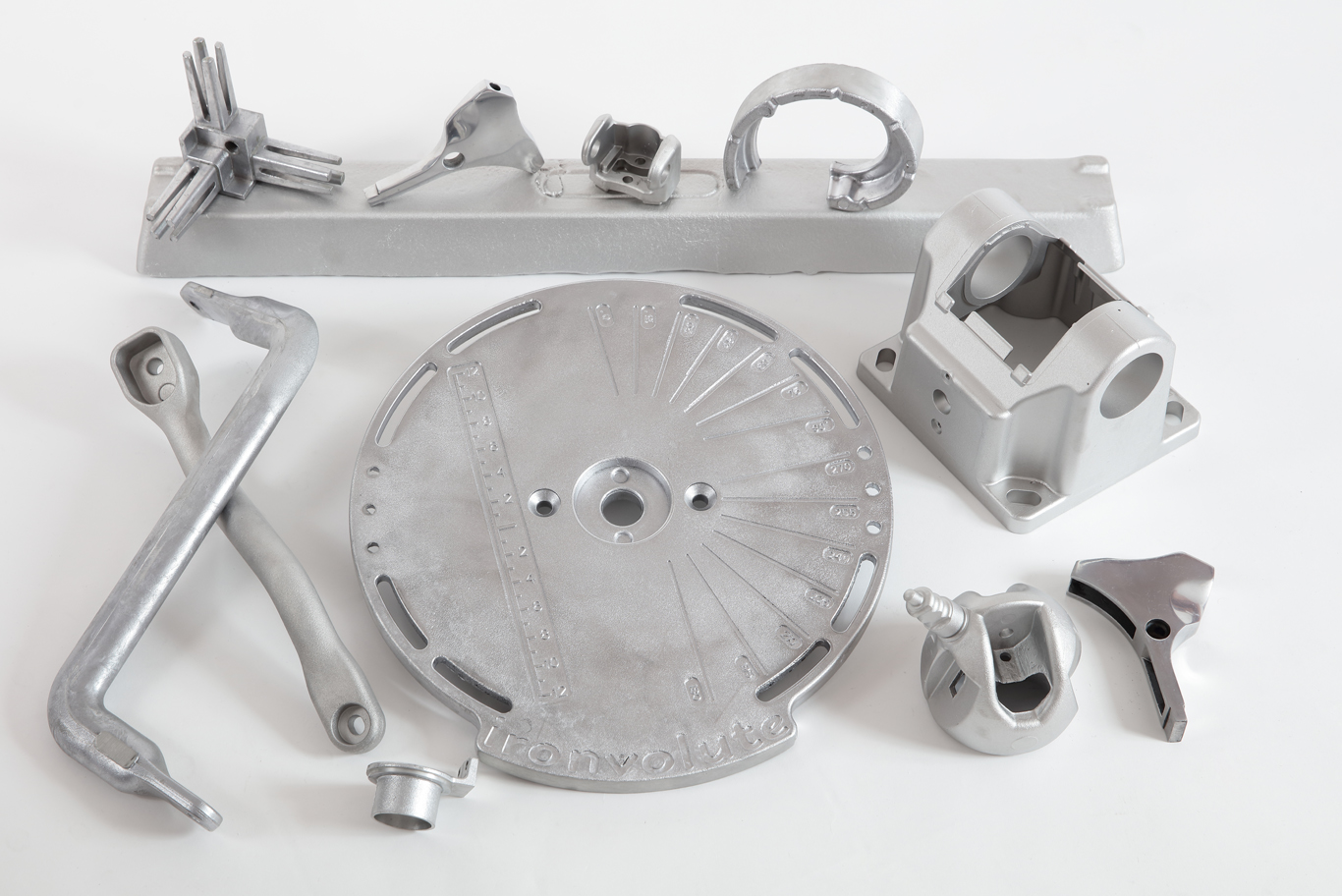

Gravity die casting aluminium

- This transformation process makes it possible to reproduce pieces of complex shapes with finely ribbed thin walls

- Shell foundry parts require a high degree of finishing which includes a series of operations such as sawing of the jet and the pockets, grinding of the joint plane, heat treatment...

- It is a fast and economical manufacturing process for the production in small and medium series of light alloy parts

- One of these main advantages is to have a high repeatability and a high tool life

Characteristics of the aluminium used in gravity die casting

- At equal volume, aluminum is 30% lighter than steel

- Aluminum is an excellent conductor of temperature, 1.8 times better than copper

- Some cast aluminum alloys can undergo a heat treatment that improves the mechanical characteristics

- Recycling aluminum is easy and economical, environmentally friendly

The various aluminum alloys used in gravity die casting

| Designation according to European Standard EN 1706 | Mechanical characteristics1 N/mm² = 1MPa | |||||

| Density | State | Rm N/mm² | Rp 0.2 N/mm2 | A% | HB | |

|

ENAC-21000 Mini AICu4MgTi |

||||||

|

EN 1706 Maxi AU4GT 1ère fusion |

T4 | 320 | 200 | 8 | 95 | 2.80 |

|

ENAC-41000 Mini AlSi2MgTi |

F | 170 | 70 | 5 | 50 | |

|

EN 1706 Maxi AS2GT 1ère fusion |

T6 | 260 | 180 | 5 | 85 | 2.70 |

|

ENAC-42000 Mini AlSi7Mg |

F | 170 | 90 | 2.5 | 55 | |

|

EN 1706 Maxi AS7G 2ème fusion |

T6 | 260 | 220 | 1 | 90 | 2.67 |

|

ENAC-42100 Mini AlSi7Mg0.3 |

||||||

|

EN 1706 Maxi AS7G0.3 1ère fusion |

T6 | 290 | 210 | 4 | 90 | 2.67 |

|

ENAC-42100 Mini 67 XB (Pièces fines) |

||||||

|

EN 1706 Maxi AS7G0.3 1ère fusion |

T6 | 300 | 215 | 17.5 | 90 | 2.67 |

|

ENAC-42200 Mini AISi7Mg0.6 |

||||||

|

EN 1706 Maxi AS7G0.6 1ère fusion |

T6 | 320 | 240 | 3 | 100 | 2.67 |

|

ENAC-43100 Mini AISi10Mg |

F | 180 | 90 | 2.5 | 55 | |

|

EN 1706 Maxi AS10G 2ème fusion |

T6 | 260 | 220 | 1 | 90 | 2.66 |

|

ENAC-44200 Mini AISi12(b) |

F | 170 | 80 | 5 | 55 | |

|

EN 1706 Maxi AS12G 2ème fusion |

||||||

|

ENAC-44200 Mini 43 X |

F | 150 | 80 | 4 | 60 | |

|

EN 1706 Maxi AS12 1ère fusion |

2.65 | |||||

|

ENAC-51100 Mini AIMg3 (pièces d'aspect) |

F | 150 | 70 | 5 | 50 | |

|

EN 1706 Maxi AG3T 1ère fusion |

2.67 | |||||

Propriétés des alliages d'aluminium utilisés en fonderie coquille

| Désignation selon Norme Européene EN 1706 | Flowa-bility | Machina-bility | Welda-bility | Polishing | Chroming | Plating | Tinning | Paint (20 to 30 microns) | Silvering Gilding |

Anodi- sation |

Corrosion resistance |

Filed of application |

| EN AC-43400 - AlSi10Mg(Fe) AS10G | A | B | C | B/C | B | B | C | B | B | E | C | Medium-sized parts, general mechanics |

| EN AC-43500 - AlSi10MnMg | A | B/C | B | D | B | B | C | B | B | E | B | Medium-sized parts, general mechanics |

| 61 D1 (AS10G) | D | B | B | C | B | B | E | Security, automotive, household appliances | ||||

| EN AC-44300 - AlSi12(Fe) AS12 | A | C | D | D | B | B | C | B | B | E | C | Very complex parts, general mechanics |

| EN AC-46000 - AlSi9Cu3(Fe) AS9U3 | B | B | F | C | B | B | C | B | B | E | D | Very Large Parts, Automotive, Household Appliances |

| EN AC-46200 - AlSi8Cu3 | B | B | B | C | B | B | C | B | B | E | D | Very Large Parts, Automotive, Household Appliances |

| EN AC-46500 - AlSi9Cu3(Fe)(Zn) | B | B | F | C | B | B | C | B | B | E | D | Very Large Parts, Automotive, Household Appliances |

| EN AC-47100 - AlSi12Cu1(Fe) AS12U | A | C | F | C | B | B | C | B | B | E | C | Medium and large series, automobile, general mechanics |

Aptitudes : A = Excellent, B = Good, C = Fair, D = Poor, E = Not recommended, F = Inappropriate

The anodization of aluminum alloy castings can be carried out on alloys with a% Si content of <4%. Aluminum alloys have better resistance to corrosion if the% of Cu is <1% and the% of Zn is <0.5%

M.C.T. Can not be in any way responsible for the exploitation of the indicative data of this commercial document