Technology Comparison

Comparison of the high pressure die casting, gravity die casting and hot foring :

Those three techniques are complementary and better meet the needs of our customers. Indeed, the high pressure die casting allows, after liquefying the metal, to inject it under high pressure in a steel mold and so obtaining pieces that can be worked with thin thickness. By this method the machining and finishing operations of the parts are often limited.

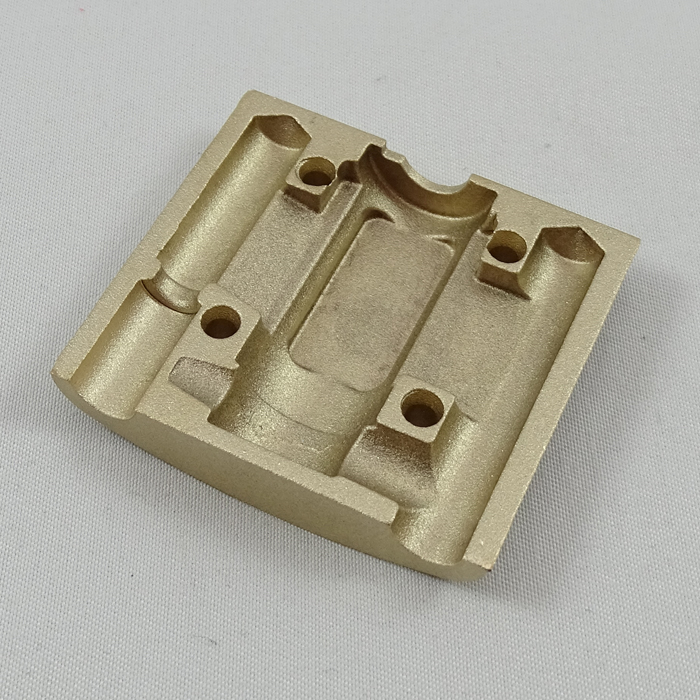

Similarly, in gravity die casting The liquid metal is cast by gravity into the mold. This means that the parts can not be so worked than in high pressure die casting and must have larger overall thicknesses. Some alloy not being able to be high pressure die casted, the gravity foundry has all its interest.

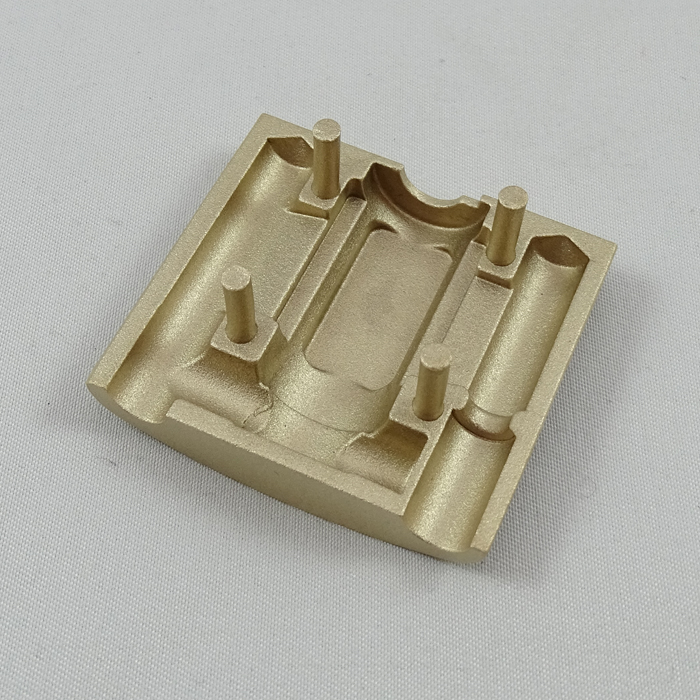

On the other hand the hot forging Consists in heating the material to make it "soft" while remaining in the solid state and deforming it by a sudden impact in a steel tooling. The part is thus formed with a burr. This burr is an overweight of peripheral material which will then be eliminated by a die cutting. This technique, due to the fact that the metal is not melted, does not destroy the original spinning of the spun material and thus produces pieces of high resistance, without premeability.

This burr is an overweight of peripheral material which will then be eliminated by a die cutting. This technique, due to the fact that the metal is not melted, does not destroy the original spinning of the spun material and thus produces pieces of high resistance, without premeability.

In a few cases, it's possible to associate those two techniques to, for exemple, couler des ébauches de forme très approchante et de matricer (frapper) ces ébauches pour les écrouir et ainsi augmenter les caractéristiques mécaniques de la pièce finale. (?)

| Characteristic | High pressure die casting | Gravity foundry |

Hot forging |

| Profitability | 5 000 to 10 000 pieces | 100 to 1 000 pieces | 500 to 2 000 pieces |

| Cost of the tooling | Important | Medium | Medium |

| Shape type | Hard worked | Moderately worked | Moderately worked |

| pieces thickness | Parts that can be fine up to 1 mm | Parts that can be fine beyond 3mm | Rather massive pieces |

| Sketch | Empty | Empty | Sometimes necessary |

| Overmoulding insert | Possible | Possible | Empty |

| Mechanical resistance | Moderate | Excellent after hardening | Excellent |

| Structure of matter | Can contain porosities | Can contain porosities | No porosities |

| Sealing | Moderate | Good | Very good |

| Surface Condition | Moderate / Good | Moderate | Moderate / Really good |

| Hardness | Hard oxidized layer | Hard oxidized layer | Ability to recover in cold calibration |

| Polishing ability | Moderate | Moderate | Good |

| Ability to be machined | Moderate | Moderate | Good |

| Production | Multi-cavity | Multi-cavity | Usually mono-cavity |

| Completion | Limited | Moderate | Important |

| Matter type | Aluminium, Brass, Bronze, Zamak | Aluminium, Brass, Bronze, Cupro aluminium | Aluminium, Brass, Bronze, Copper, CuCr, CuTe, Cupro, Titanium |

| Alloys | High pressure die casting Aluminium | Forging Aluminium | Gravity foundry Aluminium | High pressure die casting Brass | Forging Brass | Forging Copper | High pressure die casting Zamak |

| Norm and alloys type | EN AC-46000 AS9U3 |

EN 2017A AU4G |

EN AC-42200 AS7G06 |

EN 1982 60/40 |

EN 12165 CuZn39Pb2 |

EN 12165 CuA1 |

EN 10774 Zamak5 |

| Density | 2.75 | 2.79 | 2.67 | 8.4 | 8.4 | 8.9 | 6.7 |

| Technology | High pressure die casting | Hot forging | Gravity die casting foundry | Foundry | Hot forging | Hot forging | High pressure die casting |

| Caracteristic | Lightness and resistance complex shapes | Lightness and resistance | Moderate complexity shapes and resistance | Resistance | Resistance and sealing | Electric conduction | Complex shape resistance |

| Average price per kg * | 2 €/Kg | 4 €/Kg | 2.75 €/Kg | 5.25 €/Kg | 5 €/Kg | 6 €/Kg | 2.10 €/Kg |

| Average price per L * | 7.25 €/L | 13.50 €/L | 10.50 €/L | 52.50 €/L | 46.75 €/L | 56.50 €/L | 19 €/L |

| Recycling capacity | Excellent | Really good | Excellent | Really good | Really good | Really good | Moderate |

| Receiving State | Lingot | Stretch bar | Lingot | Lingot | Stretch bar | Stretch bar | Lingot |

| Transformation temperature | 700°C | 500°C | 700°C | 1050°C | 750°C | 800°C | 430°C |

| Alloys | High pressure die casting Aluminium | Hot foring Aluminium | Gravity foundry die casting Aluminium | High pressure die casting brass | Hot forging brass | Hot forging Copper | High pressure die casting Zamak |

| Processability | Good | Moderate | Good | Good | Good | Moderate | Really good |

| Minimum mechanical resistance | 240 Mpa | 390 Mpa | 320 Mpa | 350 Mpa | 350 Mpa | 200 Mpa | 331 Mpa |

| Electric conduction |

15% IACS | 34% IACS | 23% IACS | - | 27% IACS | 100% IACS | 26% IACS |

| Heat resistance |

Good | Good | Good | Good | Good | Moderate | Weak |

| Superficial hardening |

No | No | - | No | No | Yes | No |

| Ability to be machined |

Good | Good | Good | Good | Good | Moderate | Good |

| Friction ability |

Moderate | Moderate | - | Good | Good | - | - |

| riveting ability |

Moderate | Bad | Moderate | Moderate | Moderate | Really good | Really good |

| Welding Stirring |

Good | Good | - | Good | Good | Good | Good |

| Thermic treatment | No | Yes | Yes | No | No | No | No |

| Longevity of tools | Moderate | Moderate | Moderate | Weak | Moderate | Moderate | Very long |

CuTe = Tellurium Copper // CuCr = Chromium copper